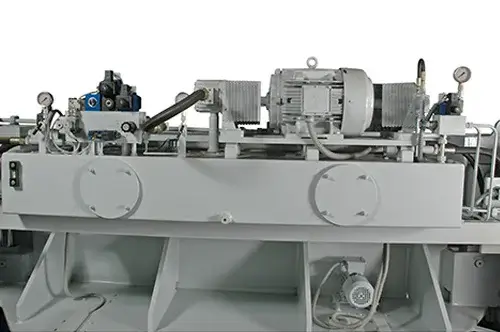

NuGEN Machineries Limited offers Trimans Variable Rake Angle NC Controlled Hydraulic Shear with two Hydraulic cylinders mounted on the cutting beam provide the shearing force. Synchronizing of the two cylinders by differential area principle simplifies the hydraulic circuit. The Variable Rake Angle of shearing blade can be adjusted by a selector switch on the Panel Box. This enables cutting of higher thickness over nominal capacity at the same time facilitating Twist-free Shearing of thin sheets, when used as per IMTMA standards. Three pre-loaded roller system guide the cutting beam accurately on both sides at an angle of 1-1.5 degree to the vertical to avoid the non-cutting edges of the blade from rubbing against the sheet and avoid trapping of cut sheets between the bottom blade and back gauge.

All four sides of top and bottom HCHCr blades are usable reducing regrinding and part replacement.

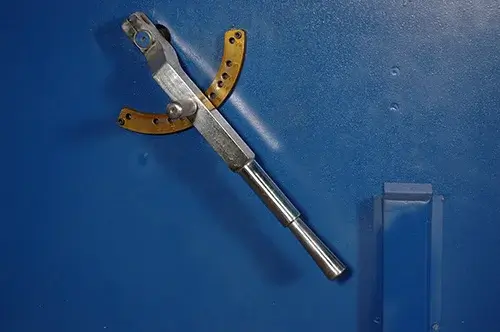

The easiest and fastest blade clearance arrangement is offered on this range of Hydraulic Shearing Machine / Shears. The blade clearance is calibrated for different thickness and can be accurately set by lever arrangement. The Hydraulic hold downs are located very close to the blade and provide positive gripping of sheets enabling distortion-free shearing of narrow strips.

Synchronization of cylinders by differential area principle eliminates complicated hydraulic circuits and imported servo valves.

The ram is guided by three point roller guides with replaceable hardened liners.

Variable Rake Angle adjustment by selector switch

Rapid blade gap adjustment by levers calibrated in thickness.

Table provided with Hardnend Transfer Bars and front sheet supports for easy feeding of plates

Shadow light indicator, Front gauging by disappearing stoppers on left squaring arm provided.

Positive holding by hydraulic hold downs before shearing avoids slippage of sheets.

Hydraulic cylinder with imported sealing elements duly honed tubes and hard chrome plates rods offer very long service life.

User friendly Motorized NC Back Gauge